Carbon Nanotube Fabrics for Superior Strength and Flexibility

Connect With Us Today

Consider us for your next production run. Why wait? Send us your questions here.

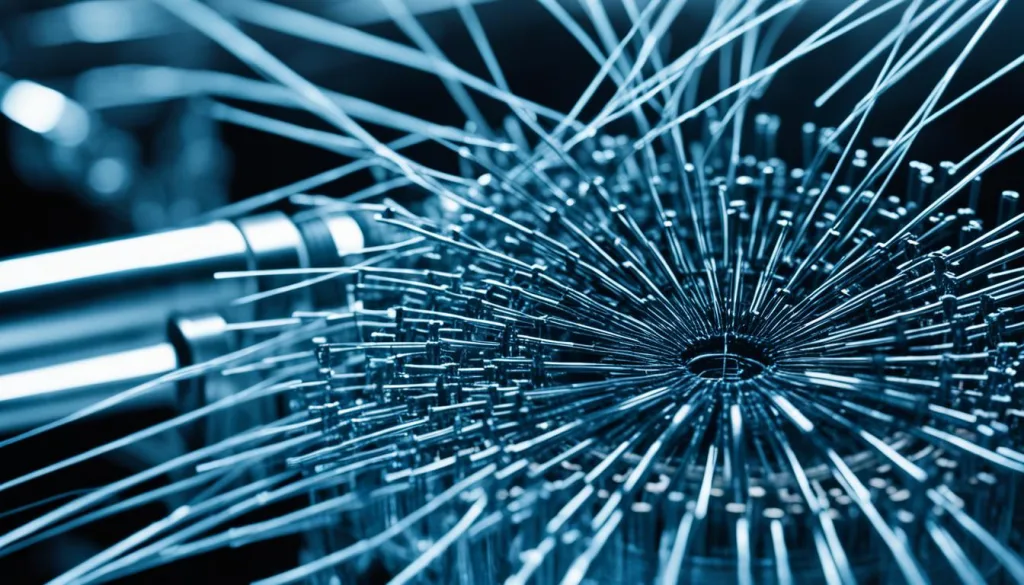

We’re stepping into a new era with advanced textiles, thanks to carbon nanotube fabrics. These revolutionary materials bring something new to the table: durability and adaptability like never before. They’re incredibly tough, resisting punctures and absorbing impacts with ease1.

Their flexibility combined with strength is unmatched. This makes them perfect for many uses, from military equipment to eco-friendly textiles1. Carbon nanotube fabrics represent a big leap in material science. They could change the way we think about materials by blending superior strength and flexibility.

Key Takeaways

- Carbon nanotube fabrics offer a significant advancement in textile durability and flexibility.

- These materials shine in the fields of safety and sustainability, suggesting a diverse scope of application in both military and civilian domains1.

- Innovative carbon-based composites promise to revolutionize the future of high-performance apparel and gear1.

- The breakthroughs in material science potentially introduce a new era of textile recycling and environmentally adaptive designs1.

- With the integration of carbon nanotubes, we see an evolution in protective clothing and accessories aimed at enhancing personal safety1.

Unveiling the Potential of Carbon Nanotubes in Textile Innovations

Exploring carbon nanotubes opens a new chapter in textile and material science. Their presence heralds a drastic shift in the fabric industry. These tubes show amazing features that outperform traditional materials like graphite.

From Discovery to Revolutionizing Material Science

Carbon nanostructured networks mark a significant milestone. Called N-nets, they play a key role in advancing textile innovations. Using electro-spraying/netting, these nets connect nanofibers, about 15nm in diameter2. Their unique design combines nanoscale and 2D connectivity, echoing carbon nanotubes and graphene. This strengthens their impact on developing new materials2.

Comparative Analysis: Graphite vs. Carbon Nanotubes

Comparing graphite and carbon nanotubes shows a major difference in performance. Carbon nanotubes excel with flexibility at 1050 MPa and great electrical conductivity at 920 S cm-12. These traits surpass graphite, making them valuable in material science. They lay the foundation for durable, flexible, and conductive materials2. This positions carbon nanotubes as pioneers in textile innovation.

Exploring Futuristic Applications Beyond the Textile Industry

Carbon nanotubes have potential far beyond textiles. Their small size and excellent electrical traits promise to revolutionize many sectors. They can change how we make products, like effective masks and supercapacitors2. With various nanostructures possible, their use in everyday life is becoming more likely. They could advance electronics, energy storage, and medical devices2.

The potential of carbon nanotubes in leading textile innovations and beyond is clear. They are proof of our creativity and dedication to advancing material science.

The Evolution of Carbon Nanotube Fabric Production Techniques

The field of carbon nanotube fabric production has grown thanks to innovators like Phillippe Poulin and Ray H. Baughman. They set the stage for new advancements in spinning carbon nanotube threads. This has made the material more useful and available for different uses3.

Pioneering Methods by Phillippe Poulin and Ray H. Baughman

Phillippe Poulin developed a key technique for turning CNTs into soft fibers. This breakthrough lets us make fabrics that can control body heat and clean themselves without water3. Alongside, Ray H. Baughman managed to spin strong threads by combining carbon nanotubes with polymers. This step forward makes products lighter and more stable3.

Breakthroughs in Spinning Carbon Nanotube Threads

New textile compositing methods using CNTs have improved our ability to create customized CNTH materials. These materials meet specific needs like conducting electricity and energy storage3. Such progress is crucial for bringing nanotechnology into textiles and solving problems like high costs and limited production3.

The Quest for Speed: Scaling Production of Nanotube Fibers

Experts are working hard to make scaling production of carbon nanotube fabrics more efficient. By focusing on the catalysts that make production better4, scientists like Poulin and Baughman are creating new ways to serve various industries like the military, healthcare, and fashion3.

Also, adding nanoparticles into textiles is an important part of nanocomposite research. It helps create fabrics with special properties3. Yet, finding ways to make the thinnest CNT varieties remains a challenge. The structural characteristics of these nanotubes guide this effort4.

Deeply understanding single-walled and multi-walled carbon nanotubes has improved our knowledge of their strengths and heat conductivities4. Key breakthroughs in making SWCNTs in 1993 have opened more ways to use them in textiles. They stand out for their versatility and superior qualities compared to other nanomaterials43.

| Feature | Benefit | Application |

|---|---|---|

| Reduced Weight | Enhanced comfort & performance | Sportswear, Aerospace |

| Electrical Conductivity | Energy storage & device integration | Wearable Technology, Health Monitors |

| Thermal Conductivity | Temperature regulation | Protective Gear, Building Materials |

| Self-Cleaning | Maintenance reduction | Fashion, Industrial Workwear |

Carbon Nanotube Fabrics for Superior Strength and Flexibility

Carbon nanotube fabrics are changing the game in material science. They bring unbeatable strength and flexibility. These fabrics mix p-type single-walled nanotubes (SWCNTs) with a thermoplastic. They have SWCNT contents from 5 to 90 wt%. This variety means they can be used in many different ways5.

Experts are excited by these fabrics because they make things much stronger. For example, a mix of 50/50 wt% of SWCNTs and thermoplastic leads to a big jump in thermal conductivity. A particular SWCNT–TPU composite is 7 to 250 times tougher than the original SWCNT material5.

These fabrics play a big role in wearable tech. They need to stretch over 10% without breaking to work well5.

Additions to the fabric have made it even better. By adding certain polymers, the Seebeck coefficient shot up. This leap is crucial for smart clothes that convert heat to electricityExploring Flexibility in Carbon Nanotube Fabrics5.

These high-tech materials have been made and tested. Special techniques have created n-type thermoelectric materials. They show incredible efficiency in labs5.

Researchers Mytafides et al. developed Tuball films with impressive efficiency. They used both p- and n-type SWCNTs. A thermoelectric generator built with these films did very well thanks to advanced printing methods5.

Creating the best carbon nanotube fabric takes lots of testing. Researchers have looked at different mixes to find the best one. They aim for the highest tech and strength. The final product is a sheet made of TPU/SWCNT “nanofibers.” These are made with a simple, one-step process5.

The impact of carbon nanotube fabrics goes beyond their strength. They can be designed for specific tasks. This opens doors to new exciting uses. Think of cutting-edge sports gear or protective clothing.

Characteristics and Properties of Carbon Nanotube Sheets

Carbon nanotube sheets have changed the game in high-performance materials. They are known for their amazing strength-to-weight ratio. They can support 50,000 times their own weight, showing their power in engineering and materials sciencesuper-fabric6. This feature opens the door to many applications where keeping things light yet strong is key.

Understanding the Strength-to-Weight Superiority

These nanotubes are 50 times stronger than carbon steel6. This strength sets a new standard for toughness. When made into sheets, this strength becomes very useful, from armor to spaceships. These sheets are not just strong; they’re flexible too. This means they can be used in things that need to bend or handle stress well, like safety gear or changeable parts in space equipment.

Conductivity and Flexibility of Nanotube Membranes

Carbon nanotube sheets are not only strong but also great at conducting electricity and heat. They do better than copper in conducting electricity6. With their high conductivity, they fit perfectly into systems needing efficient energy use, like solar panels and smart clothesunmatched combination7. As the cost of making carbon nanotubes drops from $1,000 per pound to below $506, we’re on the brink of seeing these materials more widely used, sparking new breakthroughs in many fields.

FAQ

What are carbon nanotube fabrics?

What makes carbon nanotube fabrics special?

What industries can benefit from carbon nanotube fabrics?

How do carbon nanotubes compare to graphite?

What are the potential applications of carbon nanotubes?

Who are the researchers pioneering carbon nanotube fabric production techniques?

How are carbon nanotube fabrics produced?

What are the characteristics of carbon nanotube fabrics?

What are the characteristics and properties of carbon nanotube sheets?

Source Links

- https://www.sciencedaily.com/releases/2023/04/230419125110.htm

- https://www.nature.com/articles/s41467-020-18977-6

- https://www.mdpi.com/2673-7248/1/3/28

- https://en.wikipedia.org/wiki/Carbon_nanotube

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10580240/

- https://www.asme.org/topics-resources/content/carbon-nanotube-super-fabric

- https://phys.org/news/2013-01-nanotube-fibers-unmatched-combination-strength.html

Latest News

How Collaboration Shapes Consumer Preferences in Sportswear

Navigating Consumer Rights and Warranties in Sportswear Sales

Artificial Intelligence in Fashion Forecasting and Trend Analysis

The Shift Towards Inclusive Sizing in Sportswear: Consumer Reactions

The Global Expansion of Luxury Sportswear Brands

From Sketch to Gym: The Design Process of Fashionable Sportswear

Understanding the Role of Trade Associations in Sportswear Compliance

How Economic Trends Influence Consumer Spending on Sportswear

Learning from Successful Global Market Entries

Best Practices for Managing Cross-Cultural Teams

Using Technology to Fight Counterfeit Fashion Products

Carbon Nanotube Fabrics for Superior Strength and Flexibility

The Growth of Fitness Tracking Apparel in Health and Wellness

Exploring the Influence of Social Proof in Sportswear Purchasing

Strategies for Managing Compliance in a Multinational Operation

Trends in Global Footwear: Performance Meets Lifestyle

The Role of Artificial Intelligence in Tracking Supply Chain Operations

Evaluating the Success of Sportswear Collaborative Projects

Evaluating the Potential of Emerging Markets

Global Shifts Towards Gender-Neutral Sportswear

Share This Article

Latest Articles