Impact-Resistant Clothing: Tech Advancements for Safety Gear

Connect With Us Today

Consider us for your next production run. Why wait? Send us your questions here.

The world of workplace safety is always finding new ways to keep people safe. Impact-Resistant Clothing and Protective Gear Innovation are leading the charge. They act like a shield, keeping workers safe from harm. This breakthrough in Durable Workwear Technology is possible thanks to the teamwork between S&T and North Carolina State University’s Textile Protection and Comfort Center. They created the AMBER garment1 to protect first responders from many dangers. These significant Safety Gear Tech Advancements are setting the stage for a safer tomorrow.

Key Takeaways

- Integration of cutting-edge technology in impact-resistant clothing improves safety and efficiency.

- Development of smart garments like the AMBER provides enhanced multi-threat protection1.

- Innovative body-worn cameras that activate without manual input are being developed to assist first responders1.

- Emerging tech such as the POINTER system offers precision positioning of personnel in complex situations1.

- The advocacy and guidance of the FRRG underline the practical, field-driven focus of protective gear advancements1.

- Software developments like QuickRoute and the Lost Person Locator demonstrate the harnessing of technology for swift, smart rescue operations1.

Revolutionizing Worker Safety with High-Tech Gear

In the world of industrial safety, new technology has brought major changes. Now, it’s not just about staying safe but also stopping accidents before they happen. Technologies like Augmented Reality (AR) for training, smart PPE with health and environment monitoring, and sensors for health status are leading this change. These tools show that the future of keeping workers safe depends on humans and AI working together.

Adopting Augmented Reality for Training and Hazard Awareness

AR for training is now a key way to educate workers. It lets them practice dealing with dangers by simulating real-life situations2. AR and AI-powered helmets are also making construction sites safer by alerting workers to dangers right away2. AR is proving it can not just teach but also save lives by making workers more aware of risks.

Smart PPE: Real-Time Health and Environment Monitoring

New smart PPE is changing how safe workplaces are, especially with features like Real-Time Health Monitoring3. These tools check vital signs and tiredness to prevent accidents caused by working too hard3. Also, Environment Monitoring is key in fields like painting, where it checks for harmful chemicals3. Thanks to these AI-powered safety vests, workplaces are seeing fewer accidents and better safety practices2.

Health Status Sensors for Fit and Proximity Detection

Health Status Sensors are becoming important for making sure PPE fits well2. They help employers provide the right protective gear for their workers2. These sensors show a shift towards stopping risks before they happen with actionable data2. This approach helps create a work culture that always aims to improve safety and health2.

Gathering data from these cutting-edge technologies leads to a proactive safety approach. Training, monitoring, and quick reactions come together to protect workers.

| Technology | Implementation | Impact |

|---|---|---|

| AI-Enabled Helmets | Construction | Big drop in accidents thanks to alerts about dangers in real-time2 |

| Smart PPE with Health Monitors | Manufacturing | Fewer injuries with help in maintaining correct posture and tracking health22 |

| Environmental Sensors | Chemical Exposure | Better awareness of safety and less exposure to hazards3 |

The future is bringing AI and machine learning into safety gearsoon, not later. Innovations link to the Internet of Things and AR, changing how we see workplace safety2. Industries are now focusing on using data for decisions and monitoring in real-time. This creates a safety network that’s as clever as it is needed31. What’s driving these changes is a strong commitment to the wellbeing of workers and ongoing safety improvements.

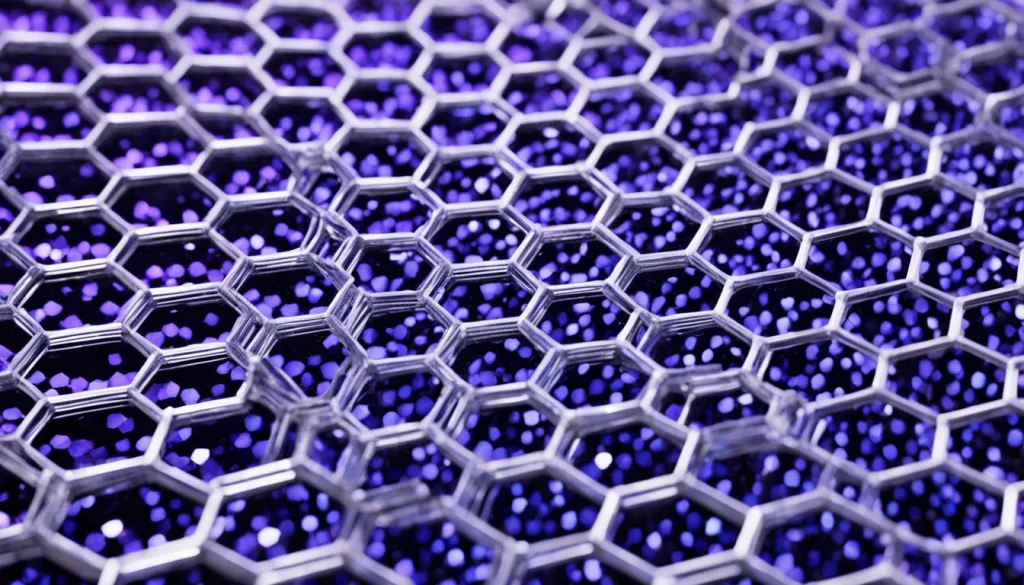

Cutting-Edge Materials for Enhanced Protection

The quest for safer workplaces leads us to new materials and tech. Things like cutting-edge materials and impact-resistant materials are changing the game. Thanks to nanotech, we now have gear that’s tough and can clean itself. This lowers the risk of getting dirty or sick4. Also, we’re leaning into using stuff that’s better for the planet. This way, we stay safe and help the earth.

Graphene is at the forefront, making protective gear lighter and stronger. It’s all about creating safe, comfy options without lowering safety4. High-performance fibers, like aramid 1414, have made slashes and heat less of a worry. They’re incredibly strong and can handle high temperatures5. It’s a huge leap forward in keeping workers safe and efficient.

Smart tech in safety gear is a game-changer. Things like sensors and the Internet of Things track health stats in the moment4. AR glasses show important info and warnings right before your eyes. They make it easier to stay safe and aware4. Exoskeletons give people extra strength and stamina. This helps avoid injuries from doing tough physical work4.

| Material Innovations | Benefits | Industries Impacted |

|---|---|---|

| Graphene-infused fabrics | Lightweight and breathable | All sectors requiring PPE |

| Aramid 1414 (Kevlar) | High strength and thermal resistance5 | Cut and heat-resistant applications |

| Nanotechnology | Self-cleaning and durable4 | Healthcare, construction, manufacturing |

| Exoskeletons | Strengthens endurance4 | Physically demanding tasks |

But these breakthroughs also bring issues like data security. We need to handle them with care4. As we bring these new materials and tech into gear, we’re making jobs safer. This effort is about protecting the people who work hard every day. Their safety is our top priority.

Impact-Resistant Clothing: Tech Advancements for Safety Gear

The creation of impact-resistant clothing has leaped forward. We owe this to new manufacturing methods and materials. We’re looking at how Nanotechnology for Barrier Improvement and Sustainable Protective Wear are changing workplace safety. Customized Safety Equipment and 3D Printing are adding exciting changes too.

Utilizing Nanotechnology for Barrier Improvement

Nanotechnology is a big player in making better protective gear. It makes fabrics strong against dangers and dirt. Protective gear is now super water-resistant. This is thanks to materials passing tests like the AATCC 127-1998 Hydrostatic Pressure Test and much more. These tests lower the chance of getting dirty from liquids6. Nanotechnology also meets strict standards ensuring safety from synthetic blood and harmful germs6.

Nanofibers have become a key part of safety outfits. They meet tough standards that protect against germs. The design and tests of this new gear follow important guidelines. These guidelines cover size and what should be on labels for safety clothes6.

The Shift to Sustainable, Biodegradable Protective Wear

The safety gear world is changing to care more for our planet. Using Sustainable Protective Wear means the industry meets global standards for safety. This happens while being kind to the environment6. We’re moving towards gear that goes back to the earth after use. This way, we keep people safe without hurting the planet.

3D Printing for Customized, Precision Safety Equipment

3D Printing is changing safety gear by making it fit perfectly. Take firefighting equipment as an example. It’s made very accurately and can take heat up to 300 °C7. 3D designs match specific standards, making sure gear performs well and lasts long7. Also, devices that help keep firefighters safe now have alarms. They beep loudly if a firefighter stops moving, making things safer7.

We’re seeing big improvements in protective clothing. New tech and materials are making workplaces safer and greener for everyone.

| Standard | Test Method | Barrier Performance |

|---|---|---|

| ASTM F1670-03 | Synthetic Blood Penetration | Nanotechnology Enhanced |

| ASTM F1671-03 | Blood-Borne Pathogens Penetration | Nanotechnology Enhanced |

| ISO 16603:2004 | Resistance to Blood Penetration | Sustainable Material Compliant |

| ISO 16604:2004 | Resistance to Pathogen Penetration | Sustainable Material Compliant |

Design Innovations Tailored for a Diverse Workforce

Enhancing worker safety with Design Innovations isn’t just about keeping up with trends. It means creating Personal Protective Equipment for a Diverse Workforce that boosts both productivity and comfort. Lenovo, a global tech leader, is at the forefront of this movement. With a wide-reaching impact in 180 markets and a workforce of 77,000, Lenovo blends high fashion with functionality in its Lenovo Tab Wear Collection8. This line is the result of partnerships with RANRA, Kit Wan Studios, and Maium8, focusing on tech-savvy and sustainable design.

Their joint efforts have birthed wearable prototypes that beautifully combine Lenovo tablets with everyday clothing8. It’s not just about safety; it’s about carving out personal space in our busy lives. Brands such as RANRA, operating between London and Reykjavik, make versatile outerwear. Kit Wan Studios from Hong Kong adds a unique blend of technology and design8. Moreover, Amsterdam’s Maium pushes the boundary with eco-friendly, stylish clothing, embodying a shift towards greener, more efficient fashion8.

These alliances show how design and technology can form a safer, more inclusive work space. They cater to different body sizes and gender needs. This change is crucial for a diverse workforce facing varied challenges.

| Brand | Focus | Innovation |

|---|---|---|

| RANRA | Transitional Outerwear | Integrates Lenovo tablets for versatility |

| Kit Wan Studios | Tech-infused Fashion | Mechanical Constructivism Aesthetics |

| Maium | Sustainability | Functional Fashion Pieces |

Conclusion

Impact-resistant clothing plays a key role in keeping workers safe in many fields. Websites like CDC show its importance. It combines new safety tech with expert insights from groups like AAMI and ASTM. This type of gear now serves as a strong defense against dangers at work6. Such innovation not only improves safety but also meets strict quality standards from ISO and BSI6.

Using Smart PPE and augmented reality has greatly improved awareness of hazards. Tests and certifications, like ASTM’s F1670-03 for blood resistance, make sure safety is not overlooked. Also, the move to nano fabrics and green materials shows the industry’s pledge to innovation and caring for the planet6.

Impact-resistant clothing today merges science, digital tech, and comfort in design. This leads to unmatched safety for workers. It marks a shift to a time when worker well-being is closely tied to the latest in safety gear. Looking ahead, progress towards a harm-free workplace is built on tech innovation and understanding safety needs6.

FAQ

How have tech advancements impacted safety gear?

What are some cutting-edge materials used in impact-resistant clothing?

How does nanotechnology improve barrier protection in impact-resistant clothing?

Is there a shift towards sustainable and biodegradable protective wear?

How does design innovation cater to a diverse workforce?

Source Links

- https://www.dhs.gov/science-and-technology/first-responder-technologies

- https://www.ishn.com/articles/114011-2024-the-year-of-ai-driven-safety-transformation

- https://www.pcimag.com/blogs/14-pci-blog/post/112003-the-role-of-smart-ppe-in-modern-manufacturing

- https://www.hse-network.com/tech-trends-how-technology-is-shaping-the-future-of-ppe/

- https://www.frontiersin.org/articles/10.3389/fchem.2021.745467

- https://www.cdc.gov/niosh/npptl/topics/protectiveclothing/default.html

- https://www.nist.gov/el/fire-research-division-73300/firegov-fire-service/personal-protective-equipment

- https://news.lenovo.com/pressroom/press-releases/cutting-edge-fashion-designers-wearable-prototype-tab-wear-collection/

Latest News

How Collaboration Shapes Consumer Preferences in Sportswear

Navigating Consumer Rights and Warranties in Sportswear Sales

Artificial Intelligence in Fashion Forecasting and Trend Analysis

The Shift Towards Inclusive Sizing in Sportswear: Consumer Reactions

The Global Expansion of Luxury Sportswear Brands

From Sketch to Gym: The Design Process of Fashionable Sportswear

Understanding the Role of Trade Associations in Sportswear Compliance

How Economic Trends Influence Consumer Spending on Sportswear

Learning from Successful Global Market Entries

Best Practices for Managing Cross-Cultural Teams

Using Technology to Fight Counterfeit Fashion Products

Carbon Nanotube Fabrics for Superior Strength and Flexibility

The Growth of Fitness Tracking Apparel in Health and Wellness

Exploring the Influence of Social Proof in Sportswear Purchasing

Strategies for Managing Compliance in a Multinational Operation

Trends in Global Footwear: Performance Meets Lifestyle

The Role of Artificial Intelligence in Tracking Supply Chain Operations

Evaluating the Success of Sportswear Collaborative Projects

Evaluating the Potential of Emerging Markets

Global Shifts Towards Gender-Neutral Sportswear

Share This Article

Latest Articles