Tech-Driven Sustainability: Smart Solutions in Textile Production

Connect With Us Today

Consider us for your next production run. Why wait? Send us your questions here.

The textile industry is moving towards eco-friendly ways as new sustainable technologies become key. These technologies are changing green textile production, making it important to use digital tools for a better environment. North Carolina State University’s work on textile innovation shows this shift. They might get up to $15 million over two years, going up to $160 million in ten years. This shows a big commitment to improving textile production in the US1.

This financial help benefits local economies and affects an industry that has over 27,000 workers in the area. There are also 30,000 people working in related jobs. This creates a strong base for smart, eco-friendly solutions in textile making1.

Emerging Innovations in Eco-Friendly Textile Materials

The world of textile making is changing fast, thanks to new, eco-friendly materials and ways. Exciting advances in sustainable raw materials are leading us to a cleaner future. In this future, biodegradable textiles and nanotechnology in textile processes lower the harm to our planet.

The National Science Foundation (NSF) is playing a big role by spending up to $15 million in two years. This could grow to $160 million in ten years for American textile innovation focusing on sustainability1. This money aims to shake up a huge $96 billion industry based in North Carolina. This area has over 27,000 textile workers, the most in the U.S.1.

Sustainable Raw Material Development

At the core of new textile changes is the use of sustainable raw materials. Makers are now using organic cotton, bamboo, and recycled materials. This cuts down on harming the environment. North Carolina, with help from academics and the industry, is making jobs and eco-friendly products grow1. Using these better materials shows we’re moving to a time when people and businesses care more about the planet1.

Impact of Nanotechnology and Biodegradability on Textile Processes

Nanotechnology is making textiles better in many ways, like making fabrics last longer, repel water, and resist dirt. And it does this without hurting the planet. Also, focusing on biodegradable textiles is key to making less trash and reusing materials for new textiles1. This big change helps cut down on pollution. It also raises the importance of textiles in many fields, all while staying green1.

Adoption of Smart Textiles: From Wearables to Medical Applications

The exciting world of smart textiles is growing into areas like wearable tech and health. These textiles can sense changes and respond, like tracking health signs and adjusting to temperature. This push into the health field doesn’t just improve care. It also starts a new age of smart, eco-friendly textiles1.

These textile advances are getting a big nod from the White House. They promised a huge $530 million through the NSF’s Regional Innovation Engines program. This includes $15 million from the government and over $365 million from other sources2. This big investment will pump money into sustainable textiles. Over ten years, this could lead to a $2 billion boost for the economy2.

The North Carolina Sustainable Textiles Innovation Engine is set to make a big change in the $90 billion textile market. With help from federal and state money, this project will bring innovation to even the smallest and overlooked areas12.

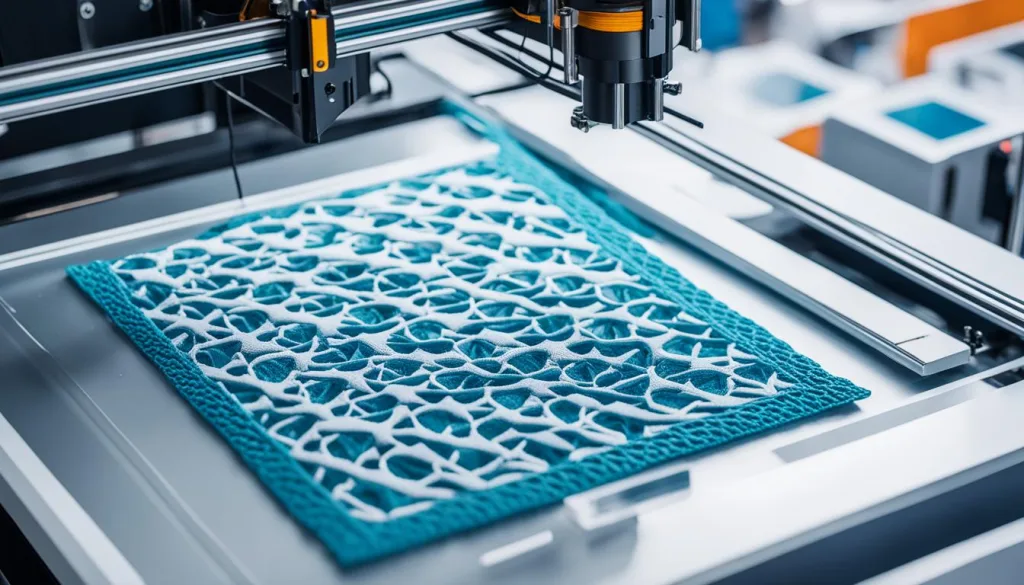

The Revolution of 3D Printing in Fabric Manufacturing

The use of 3D Printing in Fabric Manufacturing marks a significant breakthrough in textiles. It paves the way for Additive Manufacturing, Sustainable Production, Customization, and Waste Reduction. This innovation caters to both the planet’s health and people’s love for unique products.

The textiles industry uses a lot of water and materials3. However, 3D printing can greatly lower the resources needed for making clothes and home decor3. This points to a future that’s kinder to our planet and promotes smarter manufacturing.

3D printed fabrics bring new benefits. NASA uses them in space for their ability to manage heat and last long3. The University of Maryland has created fabrics that keep you cool, offering more comfort in clothes3. Plus, certain materials made with this method can support over thirty times their weight3, showing the strength 3D printing provides.

3D printing can save up to 90% of resources compared to old methods4. The Ministry of Supply turns water bottles into 3D filaments, cutting down CO2 emissions and saving 21 tonnes of CO24.

Startups like XYZ Clothing and EcoPrint are changing the game with 3D printing5. They make clothes that fit perfectly and use recycled bottles for printing5. Unmade in London offers clothes made on order to reduce waste5. This approach is gaining traction. Brands like H&M and Nike are also choosing sustainable materials, meeting consumer demand for green products5.

| 3D Printing Advantage | Environmental Impact | Consumer Benefit |

|---|---|---|

| Resource Efficiency | Minimized Water Usage | Custom-Fit Apparel |

| Enhanced Cooling Fabrics | Reduced CO2 Emissions | Advanced Comfort |

| Space-Grade Materials | Decreased Material Waste | Durability and Protection |

3D printing is changing fabric manufacturing for the better345. It’s leading to a future where making things efficiently, precisely, and in an eco-friendly way is normal. By handling heavy loads or offering made-to-order services, this new tech shows that being innovative can make production sustainable. It meets the rising call for ethical and green choices in what we buy35.

Enhancing the Textile Economy with Computer-Aided Design and Machine Learning

The rise of Computer-Aided Design (CAD) and Machine Learning is changing the Textile Economy greatly. These technologies help designers and engineers automate tasks, forecast trends, and use resources better. They bring precision like never before.

Automated Pattern Design is at the heart of this change. Brands like Zara and Adidas use CAD to make prototypes, design patterns, and cut materials more efficiently. This makes the production process smoother and helps the environment from the start6. New tech also allows for making 3D printed clothes from recycled plastics. This helps the industry be more sustainable6.

Advancements in Automated Pattern Design and Production

Machine Learning merging with CAD starts a new phase in making fabrics and clothing. This tech can quickly make custom clothing with unique designs and a focus on being eco-friendly. This is a big change from the usual mass production6. These systems support a flexible Textile Economy. They use tech to keep up with changing fashion trends quickly.

Data-Driven Fashion: Predicting Trends with Machine Learning

In retail, Machine Learning analyzes big amounts of data to guess consumer trends accurately. This way of looking at fashion helps predict what the market will want. It also makes sure inventory matches what’s needed. This cuts down on making too much and supports Sustainable Supply Chains6.

Streamlining Inventory Management Through Intelligent Systems

Better inventory management is now a big plus in the competitive clothing market. Predicting demand and planning production with Machine Learning keeps inventory just right and reduces waste. This makes supply chains stronger and more Sustainable Supply Chains. Tools like Adobe Illustrator and CorelDRAW are used not just for design but also for better managing production lifecycles. This makes managing inventory a crucial part of modern fashion economies6.

Together, these tech advancements mark a big step toward a more sustainable and economically strong textile industry. Each innovation and its use makes the industry ready for a changing world. It promises that future textiles will be fashionable, functional, ethical, and good for the planet.

Tech-Driven Sustainability: Smart Solutions in Textile Production

Tech-driven sustainability is changing the game with eco-friendly innovations. It breathes new life into textile manufacturing. North Carolina State University is teaming up with the National Science Foundation. They have a bold plan backed by up to $160 million. This plan is to make textile making more sustainable over ten years1. This effort aims to cut the carbon footprint of textiles, boost U.S. textile production, and create more jobs1.

The initiative focuses on making things more eco-friendly. It looks at the big picture with over 57,000 workers and nearly 2,000 companies involved. They’re all about reusing materials and making new products from recycled stuff1. They’re using digital tools to find sustainable ways to do things. This includes cool projects like making wind turbine blades from textiles and keeping an eye on roads1.

“With smart solutions at its core, the NSF-backed initiative is an aspirational model for rural and traditional sectors aiming toward transformative change in manufacturing processes, setting a benchmark for sustainable technology and practices in the textile industry.”1

There are big moves toward making products last longer and easier to fix. They’re also thinking about new life for old textiles, like turning them into nonwovens. These steps could mean less unemployment and bigger paychecks for the area1.

Tech-Driven Sustainability isn’t just a fancy term. It’s real and happening through teamwork from schools, businesses, and government groups. This push is putting the U.S. at the forefront of global textile making. It’s where green practices meet economic growth head-on1.

| Outcome | Expected Impact |

|---|---|

| Carbon Footprint Decrease | Lower environmental impact of textile manufacturing |

| Material Reuse and Recycle | Reduction in textiles in landfills, promotion of circular economy |

| Research and Innovation | Advancement in chemistries and new materials for textiles |

| Employment Growth | Increase in textile jobs and support for adjacent sectors |

| Sustainable Tech Use | Integration in applications such as battery components and geotextiles |

| Economic Revitalization | Higher household incomes and improved weekly wages |

The initiative’s impact will strengthen green textile manufacturing. Tech-driven sustainability is crucial for our future. We’re seeing innovative breakthroughs in textiles grow from these green practices. This ensures our textile industry’s legacy remains as innovative as its potential1.

Conclusion

This article explored how the textile production industry is changing, thanks to a focus on tech-driven sustainability and smart solutions. A study showed 47% of experts worry about future challenges, while 39% feel optimistic about improvements by 20257. Also, 86% of them believe technology will bring both good and bad changes7.

Upcoming innovations highlight the role of eco-friendly innovation. They include better digital tools which boost consumer safety and ease7. Technologies like AI, enhanced recognition systems, and instant language translation will greatly improve the future of the textile industry. They will meet customer needs with great accuracy7.

“The interplay of humans and technology will continue to redefine our everyday life, and nowhere is this impact expected to be more profound than within the realms of sustainability and textile production.” – Expert analysis7.

After the pandemic, digital communication networks have become more vital. They show our ability to adapt and be resilient in tough times7. An important 51% of Americans think their lives will keep being affected by the pandemic7. This shows why it’s crucial to add tech-driven sustainability into textile production.

Experts believe we are moving towards a time when smart solutions and eco-friendly innovation are key. We’re seeing the rise of the Internet of Medical Things, gig economy growth, and advances in cryptocurrency, among others7. These will help balance economic advancement with caring for the environment. It marks a new phase of industrial progress.

| Aspect of Change | Expected Outcome |

|---|---|

| Digital Tool Reliance | Enhanced Consumer Convenience and Safety |

| Technological Advancements | Streamlined Production Processes |

| Pandemic Aftereffects | Continued Influence on Lifestyle and Work |

| Future Predictions | ‘Internet of Medical Things,’ Urban Farming, AI Developments |

By understanding these trends, we can imagine a future where innovation leads in transforming the global textile market. The key takeaway is to actively work towards a sustainable, tech-friendly industry. This benefits everyone involved, from those who make the products to those who use them.

Frequently Asked Questions (FAQs)

How is tech shaping Sustainable Textile Production? A study says only 3% focus on Business Intelligence Systems (BIS). Yet, 10% of companies see profits drop due to higher costs and shorter order times8. Around 15% are boosting their operations with smart tech like big data8.

What’s tough about using advanced BIS? Though they’re great for making smart decisions, convincing 17% of companies to adopt them is hard8. The fashion industry’s quick changes make predicting sales tough for 7% of them8.

How do customer wants drive new tech and green making? About 20% of textile products offer lots of choice in size and style8. Fast fashion demands technologies like IoT, but 11% of companies lose money over unsold stock8. Combining eco-friendly materials with tech like 3D Printing is setting new, sustainable standards.

FAQ

What is tech-driven sustainability in textile production?

What are some emerging innovations in eco-friendly textile materials?

How is 3D printing revolutionizing fabric manufacturing?

How are computer-aided design (CAD) and machine learning enhancing the textile economy?

How do sustainable technology and eco-friendly innovation promote green textile manufacturing?

What are the key takeaways for tech-driven sustainability and smart solutions in textile production?

Source Links

- https://news.ncsu.edu/2024/01/new-nsf-center-will-advance-textile-industry-greening/

- https://www.whitehouse.gov/briefing-room/statements-releases/2024/01/29/fact-sheet-biden-harris-administration-announces-innovation-engines-awards-catalyzing-more-than-530-million-to-boost-economic-growth-and-innovation-in-communities-across-america/

- https://www.azom.com/article.aspx?ArticleID=21953

- https://www.fibre2fashion.com/industry-article/9632/is-3d-printing-the-future-of-fashion

- https://fastercapital.com/questions/how-3d-printing-startups-are-disrupting-the-traditional-apparel-industry:reducing-waste:-3d-printing-and-sustainable-design.html

- https://www.linkedin.com/pulse/fashion-tech-how-technology-shaping-future-apparel-fibre2fashion-ro7hf

- https://www.pewresearch.org/internet/2021/02/18/experts-say-the-new-normal-in-2025-will-be-far-more-tech-driven-presenting-more-big-challenges/

- https://www.mdpi.com/674766

Latest News

How Collaboration Shapes Consumer Preferences in Sportswear

Navigating Consumer Rights and Warranties in Sportswear Sales

Artificial Intelligence in Fashion Forecasting and Trend Analysis

The Shift Towards Inclusive Sizing in Sportswear: Consumer Reactions

The Global Expansion of Luxury Sportswear Brands

From Sketch to Gym: The Design Process of Fashionable Sportswear

Understanding the Role of Trade Associations in Sportswear Compliance

How Economic Trends Influence Consumer Spending on Sportswear

Learning from Successful Global Market Entries

Best Practices for Managing Cross-Cultural Teams

Using Technology to Fight Counterfeit Fashion Products

Carbon Nanotube Fabrics for Superior Strength and Flexibility

The Growth of Fitness Tracking Apparel in Health and Wellness

Exploring the Influence of Social Proof in Sportswear Purchasing

Strategies for Managing Compliance in a Multinational Operation

Trends in Global Footwear: Performance Meets Lifestyle

The Role of Artificial Intelligence in Tracking Supply Chain Operations

Evaluating the Success of Sportswear Collaborative Projects

Evaluating the Potential of Emerging Markets

Global Shifts Towards Gender-Neutral Sportswear

Share This Article

Latest Articles