The Rise of 3D Printing in Custom Apparel Manufacturing

Connect With Us Today

Consider us for your next production run. Why wait? Send us your questions here.

The fashion world is changing fast, thanks to innovative fashion technology. 3D printing in the fashion industry is making waves, turning the idea of custom 3D printed clothing into a reality. Now, designers and brands can offer one-of-a-kind pieces to their customers. This shift is changing how clothes are made and letting shoppers enjoy a custom fit.

Today’s fashion scene shows how far we’ve come with 3D printing. High-quality SLA 3D printers, once expensive, are now under $5,000. This makes the fashion future bright with both creativity and affordability hand in hand. Big names like Coach, Stuart Weitzman, and Kate Spade of Tapestry, Inc., have adopted 3D printing. They’re crafting unique hardware and jewelry, starting a new age of creativity and precision.

Key Takeaways

- High-end SLA 3D printers are now more affordable, enhancing accessibility for fashion brands.

- Luxury fashion houses like Coach are utilizing 3D printing to prototype designs rapidly.

- The integration of 3D technology in fashion trims development cycles, optimizing time and costs.

- 3D modeling and printing open new avenues for women in fashion industry roles.

- Custom product previews using 3D renderings offer consumers unparalleled customization opportunities.

Understanding 3D Printing in the Fashion Industry

The fashion world is quickly changing with 3D printing leading the way in custom clothes making. This change brings many benefits, like more creativity, better sustainability, and personalization that was once impossible. It’s a big step for how we make clothes.

The Birth of Additive Manufacturing in Apparel

Fashion creation no longer takes ages. With SLA desktop 3D printers, priced below $5,000, designers can use advanced 3D tech. It’s not just cheaper but also speeds up the design process. This means the fashion industry can keep up with fast-changing trends easily.

Technological Advancements in 3D Printed Fashion

Famous fashion companies, like Coach, now rely on 3D printing. It helps create many new products each season. This tech is proving valuable for big brands, cutting down on waste. For instance, 3D-printed knitwear makes about 30% less waste than traditional methods. This moves the industry toward more sustainable practices.

The Shift Toward Personalized Apparel with 3D Printing

Digital design and on-demand production make personalized 3D knitwear possible. This allows for instant changes based on what the customer wants. It’s a big move toward clothing that’s custom-made for each person. Women are also playing a big role in this, using 3D printing to innovate the fashion industry.

This technology is about more than just looks. It’s about making clothes in a way that’s good for our planet and more efficient. It’s a shift in both technology and culture, where being unique and caring for the environment matter more than ever.

Breaking Down the DTG Printing Market Growth

The direct-to-garment printing market growth is reshaping the industry, thanks to additive manufacturing in apparel. Experts predict the market will reach US$ 861.2 million by 2024. By 2034, it could hit US$ 1.32 billion, growing at a CAGR of 4.4%.

This growth is fueled by a surge in demand for personalized fashion. DTG technology is leading this charge.

In the United States, the DTG sector is expected to grow at a CAGR of 2.5% through 2034. Japan and the United Kingdom will likely see a CAGR of 2.6%. But the real growth is happening in emerging markets.

India is on track for a stunning CAGR of 6.7%. China is not far behind, with a CAGR of 5.9%. These figures show a global move towards personalized apparel, embracing additive manufacturing in apparel.

| Country/Region | 2024 Market Value (in US$ million) | 2034 Expected CAGR |

|---|---|---|

| United States | —* | 2.5% |

| Japan | —* | 2.6% |

| United Kingdom | —* | 2.6% |

| India | —* | 6.7% |

| China | —* | 5.9% |

| Global Market | 861.2 | 4.4% |

By 2024, cotton will cover 27.7% of the DTG market. This shows how much people still love cotton in their clothes.

Furthermore, the clothing sector will dominate 58.9% of the market. It shows how DTG is becoming a core part of garment making.

The custom T-shirt segment is also growing fast, with a CAGR of 9.7% expected from 2023 to 2033. The digital textile printing sector is set to expand even quicker. It will grow at a CAGR of 12.1% from 2024 to 2034, outpacing most of its peers.

- Historical CAGR (2019 to 2023): 4.6%

- Cotton Material Market Share in 2024: 27.7%

- Clothing and Apparels Market Share in 2024: 58.9%

- Custom T-shirt Printing Market CAGR (2023 to 2033): 9.7%

- Digital Textile Printing Market CAGR (2024 to 2034): 12.1%

Summing up, the DTG printing market is embracing new technologies. It’s changing how we make and think about clothes. With additive manufacturing in apparel, we’re entering a new era of garment creation.

“`

*Note: The “—” in the table mean specific regional market values are not provided.

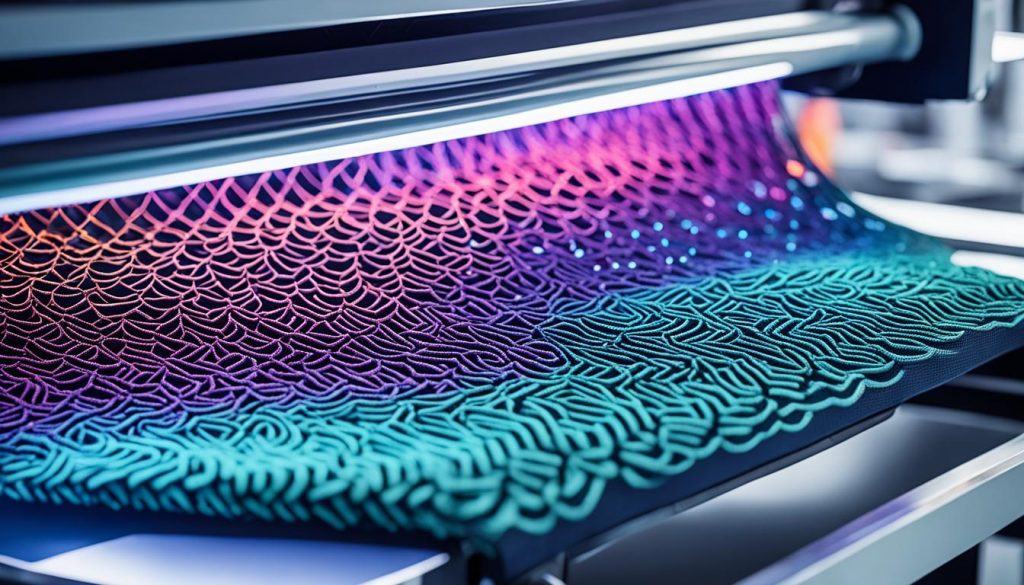

Innovative 3D Printing Techniques Transforming Garment Production

The future of 3D printed fashion is unfolding before our eyes. Innovative 3D printing techniques are changing garment production. Artisans and big companies are adopting these new methods, leaving old ways behind. This shift is driven by 3D printing advances. They offer endless opportunities for creativity and better efficiency.

Direct-to-Shape Inkjet Printers

Direct-to-shape inkjet printers have changed apparel design. These printers allow for complex and colorful designs on fabric. This is a big step from traditional screen printing. It’s like giving fabric designers the freedom of painters. They can now quickly create new designs that meet today’s fashion needs.

Advancements in Full-Color Fabric Printing

Full-color fabric printing is another big advancement. It lets designers use many colors in their creations. This opens a new world where designers’ only limit is their imagination. These changes also support a move towards a sustainable future. They reduce waste and open new possibilities in garment production.

The transformative power of 3D printing in fashion isn’t just about aesthetics; it’s a conduit for operational innovation, environmental stewardship, and the democratic dissemination of design capability.

These innovations also make economic sense. Just five years ago, commercial 3D printers cost between $50,000 and $100,000. Now, you can get advanced 3D printers for less than $5,000. This makes the technology accessible to more people.

| Statistic | Implication |

|---|---|

| Cost reduction of 3D printers from $50k-$100k to under $5k | Increased accessibility of 3D printing for small-scale designers and startups |

| Cutting development timelines with 3D technology | Agile response to market trends and consumer demands |

| Multiple brands using 3D printed prototypes | Standardization and cross-industry adoption of 3D prototyping |

| Companies like GE and BMW adopting industrial 3D printing | Establishes credibility and forecasts widespread industrial adoption |

| Diverse range of printable materials | Opens new avenues for innovation in garment materials and properties |

The job market is also changing because of these innovations. Product development is now more in demand than design. This shows how important 3D printing skills are becoming in fashion. Experts like Lizz Wiker are leading the way. They show how design, fabrication, and engineering work together in fashion.

The impact of future 3D printed fashion reaches beyond fashion. Companies like GE, Lockheed Martin, and BMW are investing in 3D printing. This marks a shift towards additive manufacturing. The possibilities in apparel are now wider, from plastics to stem cells.

In short, 3D printing is revamping garment production. It’s making the industry more sustainable, efficient, and creative. These changes are setting up a new standard in how we think about making clothes.

The Impact of Custom 3D Printed Clothing on Consumer Preferences

We are stepping into the future of fashion, where consumer preferences in custom 3D printed clothing are changing. This change goes hand in hand with technological growth. 3D printing technology adapts to new consumer wants. It allows for personalized apparel with 3D printing, meeting desires for uniqueness and personal style.

Our desire to stand out now looks to custom clothing, a reflection of ourselves created through 3D printing tech. This shift towards personalized apparel with 3D printing is reshaping how people see and buy clothes in the fashion industry.

Let’s look at the statistics showing this area’s growth:

The development and testing of new products or improvement of existing ones can be accelerated and made more cost-effective thanks to 3D printing technology.

Our interest in new fashion goes along with bigger plans for the economy and the planet. These plans support small, innovative companies that use new tech effectively.

| Aspect | Influence on Custom Apparel Manufacturing |

|---|---|

| Technological Considerations | 3D printing methods and materials redefine the creation process, opening doors to intricate and innovative designs. |

| Economic Implications | Cost-efficiency in production and scalability signifies a positive impact on the market for custom apparel. |

| Societal Impact | Custom apparel feeds into the narrative of a society valuing personalization, changing the consumer culture. |

| Intellectual Property Rights | Emerging legal discussions on copyright protection challenge the status quo of digital design ownership. |

In this world, custom 3D printed clothing is more than fashion. It shows a big change, making the customer’s choice very important. We see a clear effect on fashion trends, moving towards outfits that express the wearer’s personality.

The use of 3D printing is spreading, from medical models to clothes. This makes 3D printing crucial for future markets. Different fields are coming together, blending food design with fabrics and building techniques with fashion’s future shapes.

We are at a turning point in fashion, where consumer preferences in custom 3D printed clothing spark new developments. In short, personalized apparel with 3D printing sets the new norm.

The Sustainable Edge of 3D Printing in Apparel Manufacturing

3D printing in apparel manufacturing opens a new path for sustainable custom apparel. It’s known for its ability to reduce waste in 3D printed clothing. Additive manufacturing takes a new approach to fashion, focusing on less waste and more respect for the environment.

Reduced Waste and Enhanced Material Efficiency

The fashion industry often faces issues with overproduction and waste. But 3D printing brings a solution by using materials more wisely. This drastically reduces waste and boosts efficiency. By adopting 3D printing, we show our dedication to creating eco-friendly apparel.

Many industries, from aerospace to biomedicine, are now using 3D printing technology. This method lets us push past old limits, making clothes that are beautiful, functional, and long-lasting.

Water-Based Inks and Eco-Friendly Production Processes

We’re moving beyond just being efficient; we’re also focusing on eco-friendly 3D printing processes. Switching to water-based inks helps us lessen our environmental impact. This change fits well with our sustainable goals and meets the demand for green fashion.

To show our commitment to combining technology with sustainability, we’re sharing some data:

| Industry | Benefits of 3D Printing | Challenges | Materials Employed |

|---|---|---|---|

| Apparel Manufacturing | Customization, Speed, Reduced Material Waste | Preprocessing/postprocessing costs | Standard Thermoplastics, Graphene-Based Substances |

| Medical | Custom Prosthetics, Biomechanical Structures | Limited Material Options | Alloys, Polymeric Materials |

| Aerospace | Complex Part Production, Supply Chain Optimization | Technological Constraints | High-Performance Thermoplastics, Ceramics |

| Automotive | Rapid Prototyping, Manufacturing Spare Parts | Scaled Production Feasibility | Ceramics, Durable Thermoplastics |

By embracing eco-friendly 3D printing processes, we’re part of a movement that combines innovation with responsibility. We’re crafting a future where sustainability is a key part of our industry.

The Role of Collaboration in Advancing 3D Fashion Technology

In the fashion world, 3D printing has been a game-changer. It’s transformed how clothes are designed and made. This journey shows us the power of technology in fashion. Advancing 3D fashion technology is a shared goal between tech experts and fashion leaders. This is why collaboration in 3D printing is key to progress.

Partnerships between Tech Companies and Fashion Designers

We have seen tech and fashion join forces. This partnership has brought us amazing designs that break the mold. At events like New York Fashion Week, these collaborations shine. For example, a multicolored 3D-printed dress in 2016 stunned everyone.

Professional Development and Training in 3D Apparel Printing

Learning about 3D printing is crucial for its success. We’ve talked to experts. They stress the importance of training in advancing 3D fashion technology. New platforms are helping the community grow, from designers to those selling the clothes.

Now, let’s look at a table showing 3D printing’s impact on fashion:

| Advancement | Implications | Future Outlook |

|---|---|---|

| Multi-material printing | Allows for greater design complexity and functionality in apparel | Expected to become mainstream for durable and intricate fashion items |

| Collaborative platforms | Promotes standardization and exchange of ideas among professionals | Will likely lead to an increase in innovative applications and market expansion |

| Legal and IP considerations | Necessitates reforms to protect creators in the digital fabrication age | Anticipated to lead to a more defined and secure legal framework for 3D printing in fashion |

In conclusion, the future of 3D printing in fashion looks bright. The key to success is collaboration in 3D printing. By working together and continuing to learn, we can change fashion for the better. We aim for a world where fashion is sustainable, innovative, and more impactful than ever.

The Economical Benefits of Additive Manufacturing in Apparel

We see that economical benefits of 3D printing go beyond just making prototypes. This tech is changing custom apparel making. It shows off creative freedom and cost-effectiveness in the fashion world.

Only 2.6% of studies look at 3D printing in apparel, showing it’s just starting but could grow a lot. Thanks to insights from the National Center for Biotechnology Information, the future of 3D printing in fashion is bright.

| Material Type | Articles Count | % of Total Research |

|---|---|---|

| Polymers | 11 | 28.9% |

| Metals | 8 | 21.1% |

| Fused Deposition Modeling | 7 | 18.4% |

| Metal 3D Printing | 4 | 10.5% |

These stats show the main research areas and suggest where the best cost-effectiveness in apparel is. Polymers lead due to their good fit with 3D printing.

- Operationally efficient – 3D printing minimizes the steps from design to production.

- Reduces inventory costs – on-demand manufacturing means producing exactly what’s needed.

- Scalable – easily adjusted to accommodate small batch runs or large-scale production.

As additive manufacturing grows, businesses can better meet the fast demands of today’s retail. The economical benefits of 3D printing include less waste, better inventory management, and cool, affordable designs.

Our job is to both value and help grow this tech for better fashion standards and more choices for designers and shoppers alike.

Pioneering Brands and Designers in 3D Printed Fashion

Pioneering brands are changing how we see clothes through 3D printing. Designers with 3DFashion™ Technology are overcoming old economic hurdles. Just five years ago, high-quality 3D printers were too expensive, costing up to $100,000.

Now, these printers are more affordable at under $5,000. This change helps new designers show their creativity. It’s changing both design and business in fashion.

Leading the Way with 3DFashion™ Technology

3D modeling and printing are making fashion design faster. Brands like Coach see big cost savings with new technologies. Tapestry, Inc., which owns Coach and others, is leading in using 3D printing.

This helps them adapt quickly to new fashion trends. It shows a shift to a more flexible business model in fashion.

Many women in fashion are gaining new skills with 3D printing. This technology helps them grow in their careers. It’s shaping the future of fashion.

Iconic 3D Printed Collections and Their Global Impact

Designers like Iris van Herpen and collaborations like Julia Koerner with Adidas show the power of 3D printing. Their work has won international praise. It brings new chances for making clothes fit each person’s style and size.

Van Herpen’s detailed clothes and Adidas’s shoes show big changes in fashion. It’s a new era where personal style matters more.

3D printed fashion helps the environment too. It uses only necessary materials, reducing waste. This makes fashion more eco-friendly.

Finding new materials for 3D printing remains tough. We’re working to improve textures and colors in printed clothes. Making 3D printing cheaper and more accessible is also crucial.

The future is bright for 3D printing in fashion. It lets smaller designers be more creative. 3DFashion™ Technology is opening doors to a new kind of fashion industry. It’s about creative freedom, being inclusive, and eco-friendly.

Conclusion

Looking at the journey of 3D printing in custom apparel manufacturing, its potential to change our industry is huge. The 3D printing market is valued at USD 20.37 billion in 2023. It will grow rapidly, reaching new heights by 2030. This growth shows how important 3D printing will be for the future of fashion, blending innovation with what consumers want.

The biggest part of the market is the industrial printers, with over 76% of the revenue. Design software also plays a key role, making up more than 36% of revenue in 2023. These tools are not just making a splash; they are becoming vital to the fashion industry’s growth. But, the hesitation from small businesses about the costs of starting up shows there’s room for growth. We need to help all businesses harness the power of 3D printing.

Even with challenges, the future of custom apparel looks bright. The push for unique, eco-friendly fashion is strong. Looking forward, the story is more than about fashion. It’s about shaping how we express ourselves through clothes. As time goes on, our love for innovation will open new paths. 3D printing will be central to making fashion more personal, sustainable, and expressive.

FAQ

What is driving the rise of 3D printing in the fashion industry?

How does additive manufacturing benefit apparel production?

How significant is the growth of the DTG printing market?

FAQ

What is driving the rise of 3D printing in the fashion industry?

3D printing is growing in the fashion world for a few reasons. People want clothes that are more unique to them. They also like that it’s easier to make complex designs. Plus, it’s a step towards making clothes in a way that’s better for our planet.

How does additive manufacturing benefit apparel production?

Additive manufacturing brings big benefits. It lets clothes be tailored to fit everyone’s unique shape and style. It also cuts down on wasted materials. And, it allows for making clothes only when needed, which saves a lot of money and resources.

How significant is the growth of the DTG printing market?

The DTG printing market is quickly growing. It’s expected to be worth about US

FAQ

What is driving the rise of 3D printing in the fashion industry?

3D printing is growing in the fashion world for a few reasons. People want clothes that are more unique to them. They also like that it’s easier to make complex designs. Plus, it’s a step towards making clothes in a way that’s better for our planet.

How does additive manufacturing benefit apparel production?

Additive manufacturing brings big benefits. It lets clothes be tailored to fit everyone’s unique shape and style. It also cuts down on wasted materials. And, it allows for making clothes only when needed, which saves a lot of money and resources.

How significant is the growth of the DTG printing market?

The DTG printing market is quickly growing. It’s expected to be worth about US$1.32 billion by 2034. This shows how important new printing methods are becoming in making clothes.

What advancements are being made in 3D printing techniques for garment production?

There are new 3D printing advances happening. One is Direct-to-Shape inkjet printers that can print detailed and colorful designs on clothes. Another is the improvement in printing full colors on fabric, which gives designers more freedom.

How are consumer preferences impacting custom 3D printed clothing?

People are now wanting clothes that stand out and are special to them. 3D printed clothes meet this need by offering custom, unique styles. This trend is changing the way we think about fashion.

How does 3D printing in apparel manufacturing contribute to sustainability?

3D printing makes clothing production more eco-friendly. It does this by reducing waste and often using sustainable methods and materials. For example, using water-based inks and greener processes makes less of a negative impact on our environment.

What role does collaboration play in advancing 3D fashion technology?

Working together is key for 3D fashion tech. Tech companies and fashion designers are joining forces. They combine their tech and design skills to make new, sustainable fashion items.

What are the economic benefits of using 3D printing in apparel manufacturing?

Using 3D printing in making clothes can save money. It makes the whole process more efficient. It lets brands make clothes only as needed. This cuts down on extra stock and wastes less material.

Who are the pioneers of 3D printed fashion and what impact are they having?

Leaders in 3D printed fashion include brands using 3DFashion™ Technology, like Stratasys. They’re blending classic fabrics with new materials for innovative, greener designs. This approach is changing the fashion game.

What does the future hold for personalized fashion with the continued integration of 3D printing?

With 3D printing, personalized fashion’s future looks bright. It offers more ways to customize clothes, making fashion more sustainable. It lets everyone show their style in a unique way. And, it’s changing how we make clothes for the better.

What advancements are being made in 3D printing techniques for garment production?

There are new 3D printing advances happening. One is Direct-to-Shape inkjet printers that can print detailed and colorful designs on clothes. Another is the improvement in printing full colors on fabric, which gives designers more freedom.

How are consumer preferences impacting custom 3D printed clothing?

People are now wanting clothes that stand out and are special to them. 3D printed clothes meet this need by offering custom, unique styles. This trend is changing the way we think about fashion.

How does 3D printing in apparel manufacturing contribute to sustainability?

3D printing makes clothing production more eco-friendly. It does this by reducing waste and often using sustainable methods and materials. For example, using water-based inks and greener processes makes less of a negative impact on our environment.

What role does collaboration play in advancing 3D fashion technology?

Working together is key for 3D fashion tech. Tech companies and fashion designers are joining forces. They combine their tech and design skills to make new, sustainable fashion items.

What are the economic benefits of using 3D printing in apparel manufacturing?

Using 3D printing in making clothes can save money. It makes the whole process more efficient. It lets brands make clothes only as needed. This cuts down on extra stock and wastes less material.

Who are the pioneers of 3D printed fashion and what impact are they having?

Leaders in 3D printed fashion include brands using 3DFashion™ Technology, like Stratasys. They’re blending classic fabrics with new materials for innovative, greener designs. This approach is changing the fashion game.

What does the future hold for personalized fashion with the continued integration of 3D printing?

With 3D printing, personalized fashion’s future looks bright. It offers more ways to customize clothes, making fashion more sustainable. It lets everyone show their style in a unique way. And, it’s changing how we make clothes for the better.

What advancements are being made in 3D printing techniques for garment production?

How are consumer preferences impacting custom 3D printed clothing?

How does 3D printing in apparel manufacturing contribute to sustainability?

What role does collaboration play in advancing 3D fashion technology?

What are the economic benefits of using 3D printing in apparel manufacturing?

Who are the pioneers of 3D printed fashion and what impact are they having?

What does the future hold for personalized fashion with the continued integration of 3D printing?

Source Links

- https://www.forbes.com/sites/traceywelsonrossman/2018/02/07/3-d-printing-poised-to-revolutionize-the-fashion-industry/

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10255598/

- https://www.3dnatives.com/en/3d-printing-knitwear-220720215/

- https://www.prnewswire.com/news-releases/rapidly-evolving-fashion-drives-1-32-billion-growth-in-direct-to-garment-dtg-printing-market–future-market-insights-inc-302079712.html

- https://www.futuremarketinsights.com/reports/direct-to-garment-printing-market

- https://www.hbr.org/2015/05/the-3-d-printing-revolution

- https://www.wipo.int/wipo_magazine/en/2017/01/article_0006.html

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7231001/

- https://www.hindawi.com/journals/je/2023/7465737/

- https://hbr.org/2015/05/the-3-d-printing-revolution

- https://www.tomorrow.bio/post/how-3d-printing-is-revolutionizing-the-fashion-industry-2023-06-4727466168-3d-printing

- https://www.grandviewresearch.com/industry-analysis/3d-printing-industry-analysis

Latest News

How Collaboration Shapes Consumer Preferences in Sportswear

Navigating Consumer Rights and Warranties in Sportswear Sales

Artificial Intelligence in Fashion Forecasting and Trend Analysis

The Shift Towards Inclusive Sizing in Sportswear: Consumer Reactions

The Global Expansion of Luxury Sportswear Brands

From Sketch to Gym: The Design Process of Fashionable Sportswear

Understanding the Role of Trade Associations in Sportswear Compliance

How Economic Trends Influence Consumer Spending on Sportswear

Learning from Successful Global Market Entries

Best Practices for Managing Cross-Cultural Teams

Using Technology to Fight Counterfeit Fashion Products

Carbon Nanotube Fabrics for Superior Strength and Flexibility

The Growth of Fitness Tracking Apparel in Health and Wellness

Exploring the Influence of Social Proof in Sportswear Purchasing

Strategies for Managing Compliance in a Multinational Operation

Trends in Global Footwear: Performance Meets Lifestyle

The Role of Artificial Intelligence in Tracking Supply Chain Operations

Evaluating the Success of Sportswear Collaborative Projects

Evaluating the Potential of Emerging Markets

Global Shifts Towards Gender-Neutral Sportswear

Share This Article

Latest Articles